Closed Transfer System

The BatchBoy is a truly closed transfer system in all aspects of the machine. All liquids, and all vapors, are completely contained while being handled by the machine. Liquids are drawn into the machine by the vacuum it creates. The machine fills itself using vacuum; it is self-filling. All vapors are contained, mixed with water in the venturi and transported to the sprayer tank. Benefits to the operator are safety, reduced hazards from chemical liquids and their vapors, and compliance with recommendations of EPA and OSHA with regard to having a safe method of handling hazardous materials.

Vacuum-based transfer of chemicals

Using vacuum to move liquids is safer than using pressure dependent systems, such as a chemical pump pushing liquid through a line. By drawing liquid using vacuum, if a leak should occur, the system leaks inward. Air is drawn into the system and all liquid and vapor are still contained in the system. A pressure system leaks outward, squirting liquid or vapor to the outside of the system. The BatchBoy’s vacuum system never needs to be primed as a pump does. When your chemical container is near empty and starts to draw air with liquid, the system does not lose it’s prime.

Easy to use

The BatchBoy is user-friendly. Valves and controls are easy to operate and understand. Operations are learned quickly and performed instinctively. Mental energies can be concentrated on the spraying operation rather than the procedures of operating the machine, greatly reducing the chances of error.

Safe method of transferring chemical

The BatchBoy provides a safe means to cope with the hazards of handling agricultural chemicals. Your health is precious, it is fragile, and it is your responsibility. You are also responsible for the health of employees, family, and friends. You are risking your health when your person and clothing becomes contaminated, and you have the potential to spread the contamination, to bring it into your home and to expose others. Using a BatchBoy greatly minimizes the potential of becoming contaminated and spreading the contamination. You can enjoy peace of mind knowing you are protecting yourself, family, and employees from the hazards of chemical contamination.

Venturi powered by water

Water passes through a venturi, creating vacuum. This vacuum becomes the sole means of operating the BatchBoy. There is no need for another energy source, no need for 12 volt power, no need for a gasoline engine and no need for batteries. The unit is powered solely by water. Water going through the venturi also absorbs all vapors being produced by the vacuum as it draws chemical into and out of the measuring chamber.

Accurate measurement of liquid

Being able to accurately measure the chemical you are adding to your sprayer tank gives you more control over your spraying operation. Exact chemical measurement is a must for precision spraying. The BatchBoy accurately measures chemical volume, always. You can add the precise amount of chemical needed for the job, not too much and not too little. You can count on it. You can trust it. It never needs to be calibrated or adjusted. It will just as accurately measure chemical 10 years from now as it does today.

Sight tube

The sight tube is made of Ultra-Pure Teflon®, which is slick, slippery and has surface energy that minimizes the absorption of liquids, making it resistant to staining from chemicals. Teflon® is also compatible with a vast range of chemicals. If the sight tube does eventually become stained, it can be easily replaced without the need of tools.

Measuring chamber

The measuring chamber allows the operator to precisely measure the amount of chemical being transferred. This measuring chamber is a true volumetric measurement of liquid volume. The measuring chamber is always accurate. It never needs to be calibrated. The measuring chamber will not measure air entering the system. Viscosity or specific gravity of the liquid being measured has no effect on it’s volume. The measuring chamber is tall and slender, allowing small incremental and accurate graduations of the chamber’s volume that divide its volume into fluid ounce segments (also metric volume segments).

Stainless steel and plastic construction

All wetted components of the BatchBoy are made of either stainless steel, polypropylene, or Teflon® and elastomers are either fluorocarbon or EPDM. The unit is compatible with most chemicals used in the agricultural industry. Stainless steel construction of the measuring chamber makes a very sturdy unit, capable of withstanding a full vacuum. There is no deterioration or weakening of the measuring chamber from sunlight or hot and cold weather.

Rinsing system

The BatchBoy features a rinsing system that allows the operator to rinse the complete machine in just a few seconds by opening just one valve. A complete rinse of the machine between each batch of chemicals minimizes the chance of cross-contamination of chemicals or the possibility of coagulation of chemicals. Rinsing keeps the machine clean and clear of residual chemicals that can gum up and cause sticking of moving parts. Rinsing also keeps the sight tube clean and clear of chemicals to minimized the chance of staining from chemicals.

Complete drainage

The BatchBoy is designed so there are no pockets, no hose loops, no dips or traps in the machine to catch or hold liquid. The entire machine will drain completely. The measuring chamber drains completely empty directly into the venturi, which drains directly into the plumbing. All plumbing drains to the outlet port of the unit. This complete drainage assures no residual chemicals are left in the machine and assures that when rinsing, all rinse water is drained out of the machine. Complete drainage also makes winterizing the machine a task of simply draining the machine.

Control valve

The control valve performs several functions. It is primarily used to select either the filling or the emptying operation of the BatchBoy. When the control valve is positioned to EMPTY it also vents the measuring chamber, allowing air to enter the measuring chamber so liquid can be drawn out.

Master valve

The master valve directs incoming water, either to divert inlet water through the venturi so the machine can produce a vacuum, or to allow inlet water to pass directly through the BatchBoy. While diverting water through the venturi, the flow rate going to the sprayer is reduced, which allows the operator to transfer more chemical into his sprayer per gallon of water going to his sprayer. Then, when the operator is finished transferring chemical, he can open the master valve, allowing him to “top off” his sprayer tank at the full flow rate of his transfer pump.

Chemical inlet valves

There are four chemical inlet valves mounted directly to the measuring chamber. The measuring chamber also has connections for four additional valves. With these additional valves, the BatchBoy can be directly connected to up to eight different chemical containers at the same time. The chemical valves being mounted directly to the measuring chamber eliminates the need for a manifold, minimizing the chance of chemical cross-contamination.

Auxiliary water valve

The auxiliary water valve provides water to the front of the machine. This water source can be used to add water to chemical containers for rinsing, to rinse off equipment, or to add water to powdered chemicals to turn them into a slurry. CAUTION: The liquid provided to this valve is the carrier liquid you are using. If you are using 28% liquid fertilizer as your carrier, then 28% liquid fertilizer will come out of this valve.

Inlet strainer

The purpose of the inlet strainer is to catch debris before it enters the machine, safeguarding against the venturi or valves becoming clogged or plugged.

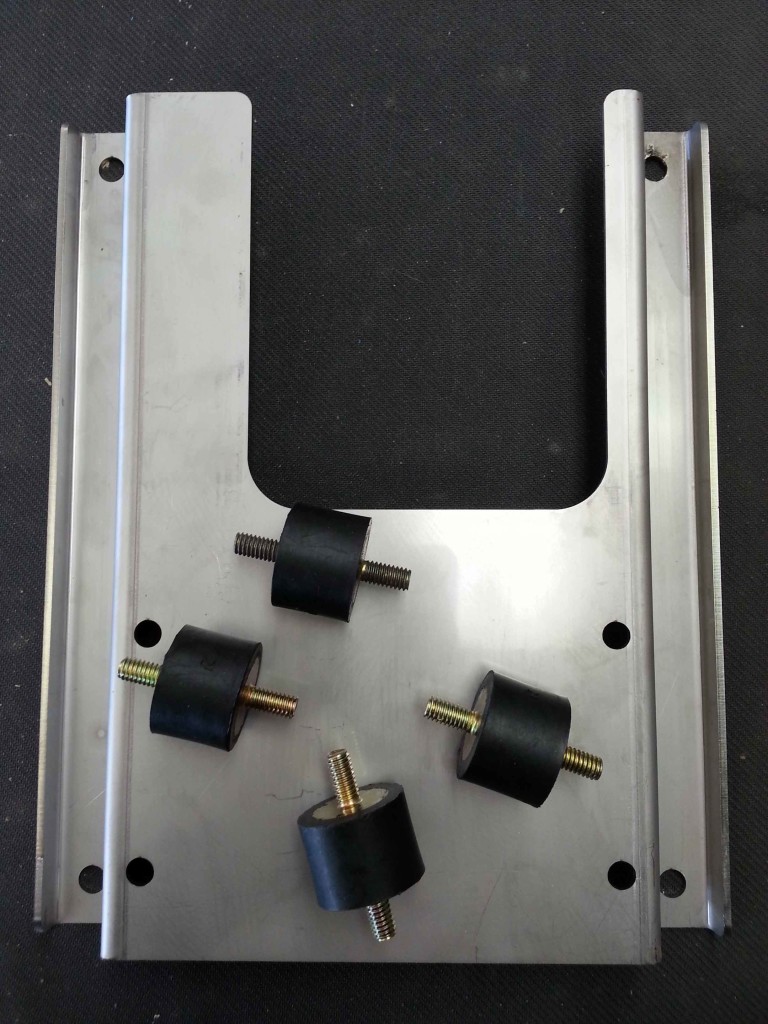

Pump mounting plate

A pump plate mounted on rubber vibration isolators is available. This is a convenient location to mount the water transfer pump. The rubber feet dampen vibrations that can cause the liquid level inside the sight tube to quiver.